Product Details

Product Introduction

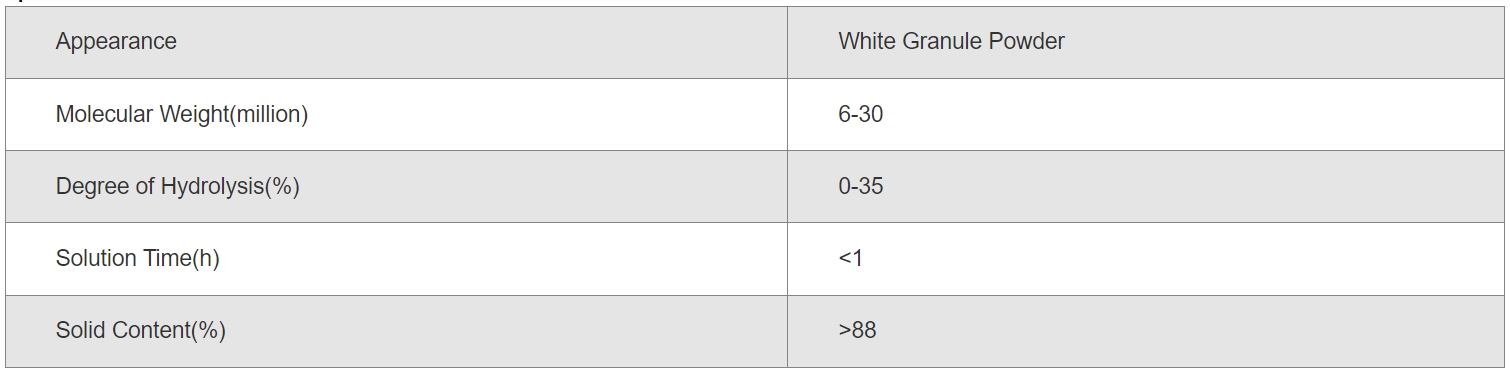

Polyacrylamide (PAM) is a highly efficient chemical additive, categorized into four types: anionic, cationic, nonionic, and zwitterionic. Its molecular formula is C3H5NO and its CAS number is 9003-05-8. PAM has also received multiple international certifications, such as ISO, S9001, ISO14001, and OHSAS, ensuring its quality and safety. Typically packaged in 25KG paper-plastic composite bags, PAM can also be customized based on order specifications. This product finds extensive application across various industrial sectors, primarily in the transportation of both crude and refined oil through pipelines. It effectively reduces flow resistance, which in turn increases pipeline throughput and minimizes energy consumption. Moreover, PAM significantly inhibits pipeline corrosion. It appears as a white granular powder with a molecular weight range of 6-30 million, a degree of hydrolysis between 0-35%, a solution time of under 1 hour, and a solid content exceeding 88%.

Advantages and features

1. Exceptional efficiency: Our high-energy PAM thickener demonstrates outstanding flocculation, thickening, and drag reduction properties, making it suitable for diverse industrial usage. 2. Premium raw materials: We utilize high-purity materials with a molecular weight ranging from 6 to 30 million, ensuring stability and efficacy for the product. 3. Comprehensive certifications: Our product has met multiple international standards, including ISO 9001, ISO 14001, and OHSAS, assuring quality assurance. 4. Versatile packaging: Standard packaging in 25KG paper-plastic composite bags can be tailored to customer specifications for easy transport and storage. 5. Resistance to corrosion: The product effectively inhibits corrosion during pipeline transportation, thereby prolonging equipment lifespan and minimizing maintenance expenditures.

Application Scenario

1. Enhancing pipeline throughput and minimizing energy consumption through the transportation of crude oil and refined oil products via pipelines. 2. Boosting treatment efficiency in the industrial wastewater management and urban sewage treatment sectors. 3. Facilitating solid-liquid separation and thickening processes in industries such as mining and sand washing.

.png)